THE EMERGING FIELD OF CELLULOSIC NANOMATERIAL PROMISES A SUSTAINABLE TECHNOLOGY

By Carrie Madren

It’s no exaggeration to say that society as we know it is dependent on trees. For centuries, humans have harvested trees for a wide variety of uses. From our books to the wooden bookshelf they sit on, fruits, nuts, lumber, paper and maple syrup, forest products are all around us. And it’s not just the products we can see. Cellulose, tiny fibers that make up wood, is found in dinnerware, cellophane and even rocket fuel.

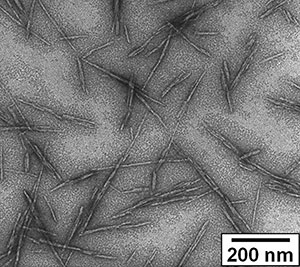

Now, 21st century researchers are gleaning a new material from trees: Nanocellulose, cellulose broken down to the nano-scale. These tiny particles come in two structures: short, rigid nanocrystal rods and longer, flexible, spaghetti-like nanofibrils. Visualizing the miniscule scale of this material takes some work of the imagination. Take a strand of your hair between your fingers. Depending on your hair type, this single strand might be anywhere from 80,000 to 100,000 nanometers wide. Now imagine a structure just six nanometers wide — approximately .007 percent of a strand of hair. That is the width of one nanocrystal rod or nanofibril. Lined up side by side, more than 4 million of these could fit in a single inch.

THE AMAZING NANOCELLULOSE PARTICLE

Don’t let their size fool you. These tiny particles pack in powerful properties. Nanocellulose is strong and lightweight. The super-strength of cellulose nanocrystals and fibrils is “strength in the order of Kevlar,” says Alan Rudie, supervisory research chemist at the Forest Products Laboratory in Madison, Wisc. Its unique properties make it a prime candidate for improving end-products as diverse as vehicles, sidewalks and paint.

For example, cellulose does not absorb light, so cellulosic nanomaterials can be made into clear films or composites such as impact-resistant windows. Rudie has had discussions with a well-known logging equipment supplier about the possibility of developing these windows for logging vehicle windshields, which are often assaulted by rocks kicked up by cutting blades. “ come at their cab windows with almost ballistic speeds,” Rudie says.

Loggers aren’t the only ones for whom nanocellulose could improve life behind the wheel. Other companies see the potential for lightweight, tree-harvested nanomaterial in steel or even foam padding. Cellulosic nanomaterials could be substituted in just about anything that contains fibers. Such lighter, better-reinforcing materials in cars would help improve fuel economy and reduce carbon emissions.

Skipping the car trip to get around on your own two feet? The sidewalks of the future could contain nanocellulose too; it can be used as a plasticizer and reinforcing material in cement.

Nanocellulose can also help modify the viscosity of paints, cosmetics and even pancake syrup, explains Robert Moon, materials research engineer at the U.S. Forest Service. In the case of paint, nanocellulose’s distinct properties could help paint to go on smoothly and then set with less dripping.

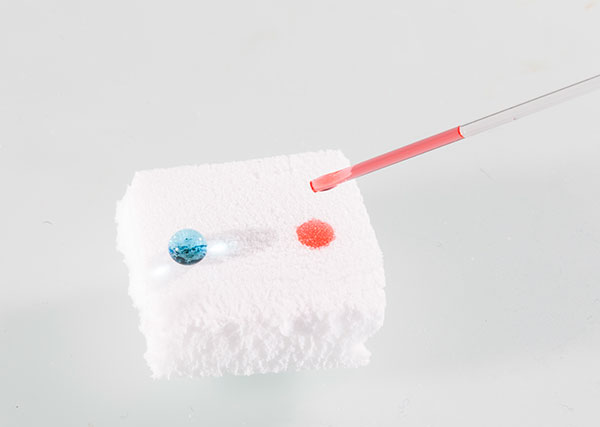

Scientists have even invented new products using nanocellulose: Researchers at the University of Wisconsin-Madison created a water-repelling aerogel, or special sponge-like foam, that floats on water and soaks up oil — a product that could be useful for oil spill clean-ups and more, explains researcher and professor of biomedical engineering Shaoqin Gong of the Wisconsin Institute for Discovery in Madison, Wisc. The oil-soaked aerogel can even be squeezed out and reused.

And what if one day, these tiny particles could even help heal our bodies? Researchers are studying how nanocellulose could help form blood vessels and new bone.

PRIMED FOR SUSTAINABLE PRODUCTION

As scientists continue to learn how to best generate cellulosic nanomaterial, they’re also figuring out how to produce it more efficiently and cost-effectively.

“One of the big advantages of cellulose as a nanomaterial is that it’s abundant and renewable,” says Michael Goergen, director of P3Nano, the new public-private partnership between the U.S. Forest Service Forest Products Laboratory and the U.S. Endowment for Forestry and Communities. “Reducing the expense of producing nanomaterial will make it more attractive in the marketplace overall.”

It’s not just expense that can be reduced, but also waste. “The other potential advantage of nanocellulose is that you don’t need to have the best wood,” Moon says, and tree species doesn’t matter. So while a lumber company wants prime wood from the tree’s core, nanocellulose can come from branches, wood chips or other parts of the wood waste stream. “These particles are so small, we can get them from the less desirable wood,” he says. “In that way, we can get more from every single tree.” If these technologies advance, a budding nanocellulose industry could tie in to the current infrastructure of pulp, paper, bio-fuel or other forest-centric industries. So, as other products are produced, cellulose nanoparticles can be one type of material that’s extracted.

And as a biodegradable resource, nanocellulose won’t persist forever in the environment or landfills. “We believe that it’s going to be sustainable, recyclable, compostable,” Rudie says.

“That might be good for products such as electronics,” says Moon, “where we produce a lot of plastic that takes a long time to degrade. By using nanocellulose, we’re putting a greener component within the plastic itself.” Similarly, nanocellulose might help to lessen the impact of popular disposable products such as coffee cups. Using polymers that contain nanocellulose would help the product to biodegrade.

And the benefits of adding nanocellulose to products go beyond the environmental. Once this new technology catches on, a nanocellulose industry could have a $600 billion worldwide impact by 2020, according to U.S. Forest Service estimates.

Companies and researchers are currently trying to get the material to the point of commercialization for use in practical products. Other nanomaterials are already being used in commercial products. If you have odor-absorbing socks, there might be nanosilver in them, for example. Nanosilver is also used in some medical products today.

To help advance nanocellulose commercialization, the Forest Products Laboratory opened up a new $1.7 million nanocellulose pilot plant in 2012 — the first of its kind in the U.S. The partnership will also help speed the development of the first U.S. commercial facility for producing nanocellulose. In addition, the new P3Nano partnership has dedicated some $3 million to funding nanocellulose research by individuals, universities, companies and other research groups.

The future is here. And it’s tiny.

Carrie Madren is a freelance writer based in northern Virginia. www.carriemadren.com